Product Introduction:

The electronic axis high-speed gravure printing machine is a new generation product developed by our company using new structures and technologies at home and abroad. This equipment integrates high-precision and high-automatic control of light, electricity and gas. It uses a high-performance control system to perform full servo control on each unit of the equipment, and realizes computer console control and remote control of the printing machine. The equipment has high color registration accuracy and less registration waste. It is suitable for multi-color and multi-layer high-speed printing of roll-shaped plastic films, cellophane and other materials. It is currently a leader in high-end equipment at home and abroad.

The whole machine is equipped with the pneumatic low-friction shaftless plate loading device pioneered by our company, which saves time and effort in loading and unloading the printing plate, accurately positions the printing plate in the horizontal direction, and improves the pressure strength of the printing plate. The ink scraper adopts a movable shaft scraper structure, which makes the ink scraping more stable in high-speed printing.

The high-speed non-stop automatic cutting mechanism has little impact on the fluctuation of overprinting during cutting and has fast recovery. The mechanical parts of the whole machine are made of high-quality alloy cast iron, carbon structural steel and alloy steel. The main parts have undergone strict stress removal and surface strengthening treatment processes, making the whole machine high in strength, good in mechanical precision retention and extended in service life.

The drying system is a high-efficiency, low-solvent residual structure that reduces heat loss. The independent wind knife design optimizes the dynamic and static pressure conversion of air supply to ensure the uniformity of air output. The high wind speed, large flow, and low temperature drying method can improve the drying quality and reduce solvent residue. The negative pressure design of the oven prevents hot air from overflowing. The single-color group has intelligent continuous temperature control, which is convenient and high-precision.

The box has a pneumatic opening and closing design, which is convenient for threading and cleaning.

The novel appearance design puts all the control parts on the same horizontal line, highlighting the humanization, the control parts for reeling and unreeling are inclined, making the control more convenient and quick.

This machine has a reasonable structure and complete supporting facilities. Its product quality and performance have reached the world's advanced level recently. It can replace imported products. Its performance-price ratio is better than that of similar products at home and abroad. It is the first choice for the majority of users.

Features

1. Equipment composition: mainly includes the following components: loading, unwinding, cutting, EPC, unwinding traction, printing, drying, cooling, receiving, traction, winding and cutting, unloading, etc.

High-speed gravure printing machine JA -1050-10

Fujian Jiuan Machinery Manufacturing Co., Ltd.

2. Function description: Through the operation of the above mechanical components, the combination of electrical and pneumatic control systems is effectively controlled at high speed to perform color printing on the printing substrate agreed in the contract, realizing the printing function of surface printing or back printing.

1. Maximum printing width: 1050mm

2. Maximum machine speed: 450m/min

3. Machine printing speed: 380m/min

4. Plate diameter, printing length: Ф118mm-Ф300mm, 370mm-942mm5. Registration accuracy: Vertical automatic registration accuracy: ±0.10mm (whole machine) Horizontal automatic registration accuracy: ±0.10mm (whole machine)

7. Maximum unwinding diameter: Ф600mm

Maximum rewinding diameter: Ф600mm

9. Material deviation correction: deviation correction rotary frame

10. Rewinding and unwinding mechanism: independent turret type two-way rotation double-axis double-station

11. Ink supply form: rubber roller ink delivery, circulating ink supply

12. Automatic lateral movement of the ink scraper: 10mm13. Maximum imprinting force: 350Kg/full width

13. Maximum imprinting force: 350Kg/full width

14. Main drive form: independent drive of servo motor without transmission shaft

15. Tension control mode: four swing roller closed loop control

16. Tension control range: 3-20Kg/full width

17. Tension control accuracy: ±0.2Kg

18. Material strip cutting: automatic cutting at high speed without stopping

Air-top air shaft19. Material roll paper core and assembly form: inner diameter Ф76mm, outer diameter Ф92mm,

20. Drying form: prepared by customers

21. Minimum air source pressure: 0.6Mpa

22. Cooling water: 13T/H

23. Printing color number: 9 colors

24. Total machine power: 80KW (heating part is provided by customers)

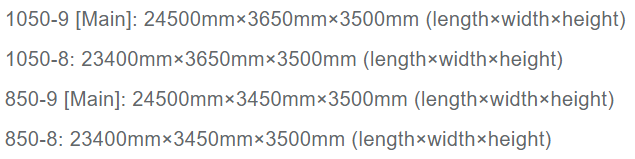

25. Machine main body appearance size: 25100mmx3850mmx4050mm (length x width x height)

26. Machine weight: 52 tons

27. Wallboard thickness: 50

28. Process flow: from left to right

29. Machine appearance: ivory white